When it comes to getting the best performance from your CNC machine, choosing the right carbide insert is very important. Carbide inserts help improve cutting performance, extend tool life, and ensure the quality of your finished products. However, with so many different types and configurations available, selecting the right one can feel overwhelming.

In this guide, we’ll walk you through everything you need to know about carbide inserts—from the basics to choosing the right type for your CNC machine.

What Are Carbide Inserts?

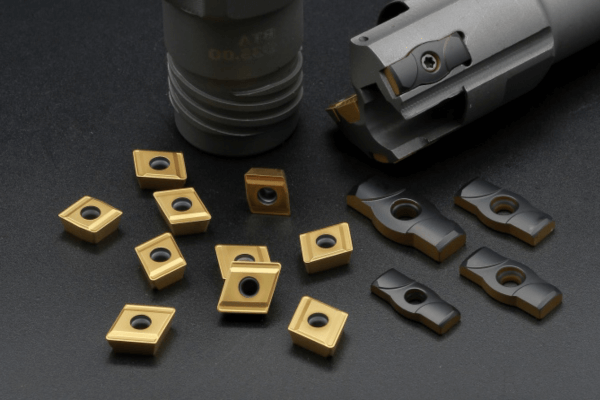

Before you start selecting carbide inserts, it’s important to understand what they are and how they work. Carbide inserts are small, replaceable cutting tools made from tungsten carbide. This material is known for its hardness, wear resistance, and ability to handle high temperatures.

Carbide inserts are used in CNC turning, milling, and drilling to cut different materials like steel, stainless steel, aluminum, cast iron, and non-ferrous metals. Unlike solid cutting tools, carbide inserts are indexable—this means you can rotate or replace them once the cutting edge wears out, saving you time and money.

Factors to Consider When Choosing Carbide Inserts

There are several things to think about when selecting the best carbide insert for your machine. Here’s a breakdown of the key factors:

a.Insert Type (Shape and Geometry)

Carbide inserts come in different shapes and sizes, and each shape works better for certain cutting tasks. Here are some of the most common types:

- WNMG Inserts: These wedge-shaped inserts are great for CNC turning. They provide good chip control and are perfect for cutting ferrous materials (like steel) and non-ferrous metals.

- CNMG Inserts: These diamond-shaped inserts work well for both rough and fine cuts in turning. Their versatile design gives them longer tool life and smoother finishes.

- TNMG Inserts: These triangular inserts are good for both light and heavy cutting. Their multi-edge design lets you use each corner, which helps maximize tool life.

- VCGT Inserts: These are wiper inserts, designed for high-speed CNC milling. They’re perfect for getting a fine surface finish, especially on stainless steel and aluminum.

b.Material and Grade

- P-Grade Inserts: Great for general-purpose cutting, like cutting steel and cast iron. They balance wear resistance and toughness.

- M-Grade Inserts: Designed for high-temperature applications, like when cutting stainless steel or titanium alloys. These inserts can handle heat better than other types.

- K-Grade Inserts: Perfect for cutting hardened steel or tough materials. They provide extra wear resistance in demanding conditions

c.Coatings and Surface Treatment

The coating on a carbide insert helps it last longer and perform better. Here are a few types of coatings:

- TiN (Titanium Nitride): A popular coating that offers excellent wear resistance, making it great for cutting low-carbon steels and non-ferrous metals.

- TiAlN (Titanium Aluminum Nitride): This coating is better for high-speed operations. It’s ideal for stainless steel and high-temperature alloys.

- CVD Coatings (Chemical Vapor Deposition): These are the toughest coatings, offering enhanced hardness and wear resistance for high-performance milling and turning.

d.Rake Angle

The rake angle affects how the insert cuts and how much force is needed. It also impacts the quality of the finished surface. Here’s what you need to know:

- Positive Rake Angle: Good for softer materials like aluminum. It reduces cutting force and helps achieve a smoother finish.

- Negative Rake Angle: Better for harder materials like stainless steel and cast iron. It provides more stability and strength while cutting.

e.Cutting Speed and Feed Rate

Carbide inserts perform best at specific cutting speeds and feed rates. Match your insert with the correct settings on your CNC machine to get the best results. Keep these factors in mind:

- Material hardness (soft, medium, or hard)

- Cutting depth

- Desired surface finish

- Tool life expectancy

By using the right insert, you can improve both productivity and tool life.

How to Match Carbide Inserts to Your CNC Machine and Material

a.CNC Machine Compatibility

Different machines require different types of inserts. For example:

- CNC Lathes: For turning, inserts like CNMG, TNMG, or WNMG are best. These inserts offer stable cutting for both roughing and finishing.

- CNC Mills: If you’re using a vertical milling machine, VCMT or Wiper inserts work well for high-speed cutting and achieving a smooth finish.

b.Material Considerations

Here’s how to match inserts to specific materials:

- Steel: Use P-grade inserts with TiN coatings for general-purpose cutting.

- Aluminum: Choose positive rake inserts with TiN or TiAlN coatings for smoother cuts and better chip flow.

- Stainless Steel: Go for M-grade inserts with TiAlN or CVD coatings for heat resistance.

- Cast Iron: Use K-grade inserts with CVD coatings for better toughness and wear resistance.

Choosing the Right Carbide Insert Supplier

When picking a supplier, consider these factors:

- Quality Control: Look for suppliers who follow industry standards (like ISO 9001).

- Delivery Times: Choose suppliers who can deliver quickly, especially if you need custom inserts.

- Customer Support: Find suppliers who offer technical support and product guidance.

Final Tips for Choosing the Right Carbide Insert

- Test Inserts: If possible, test out different inserts to see which works best on your CNC machine.

- Consult Experts: Don’t hesitate to ask your supplier or manufacturer’s technical team for advice.

- Regular Monitoring: Keep track of how well your inserts are performing to make adjustments when needed.

Conclusion

Choosing the right carbide insert is essential for getting the best performance from your CNC machine. By understanding the types of inserts, material grades, coatings, and other factors, you can make smarter choices that improve efficiency and productivity. Whether you’re a beginner or an experienced machinist, selecting the right carbide insert will help your operations run smoother and last longer.

Remember, carbide inserts are an investment. Choose wisely, and your CNC machining will become more efficient, with better surface finishes and longer tool life.