Key Takeaway:

Choosing the right APMT inserts for your CNC machine can drastically improve machining performance, reduce costs, and extend tool life. In this guide, we’ll break down the essential aspects of APMT carbide inserts and how to select the best one for your needs.

Introduction: What Are APMT Inserts and Why Are They Important?

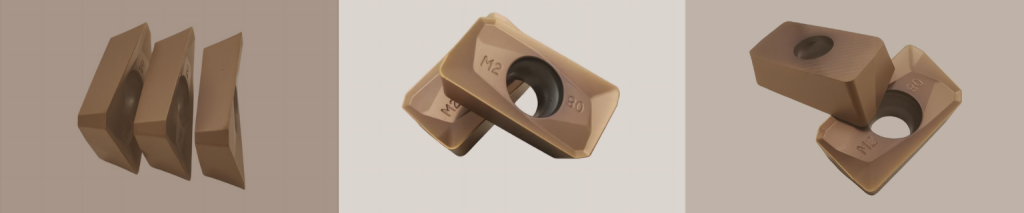

What is an APMT Insert?

APMT inserts are precision-cutting tools made from tungsten carbide. They’re commonly used in CNC machines for turning, milling, and drilling operations. These inserts are indexable, meaning they can be rotated or replaced when they wear down, helping to reduce downtime and increase productivity.

Why are APMT Inserts Critical for CNC Machining Operations?

APMT inserts are essential for achieving smooth cuts, minimizing tool wear, and ensuring the highest surface quality. They can handle high cutting speeds, and they work well with a variety of materials like steel, aluminum, and stainless steel. Visit Boyo Cutting Tools to explore our range of APMT carbide inserts.

Understanding APMT Inserts and Their Importance in CNC Machining

What is an APMT Insert?

APMT inserts are indexable carbide tools used in CNC machining. These inserts are crucial in delivering precision during various machining operations, such as turning, milling, and drilling. The key advantage is that they can be easily swapped out when worn, reducing downtime and increasing machining efficiency.

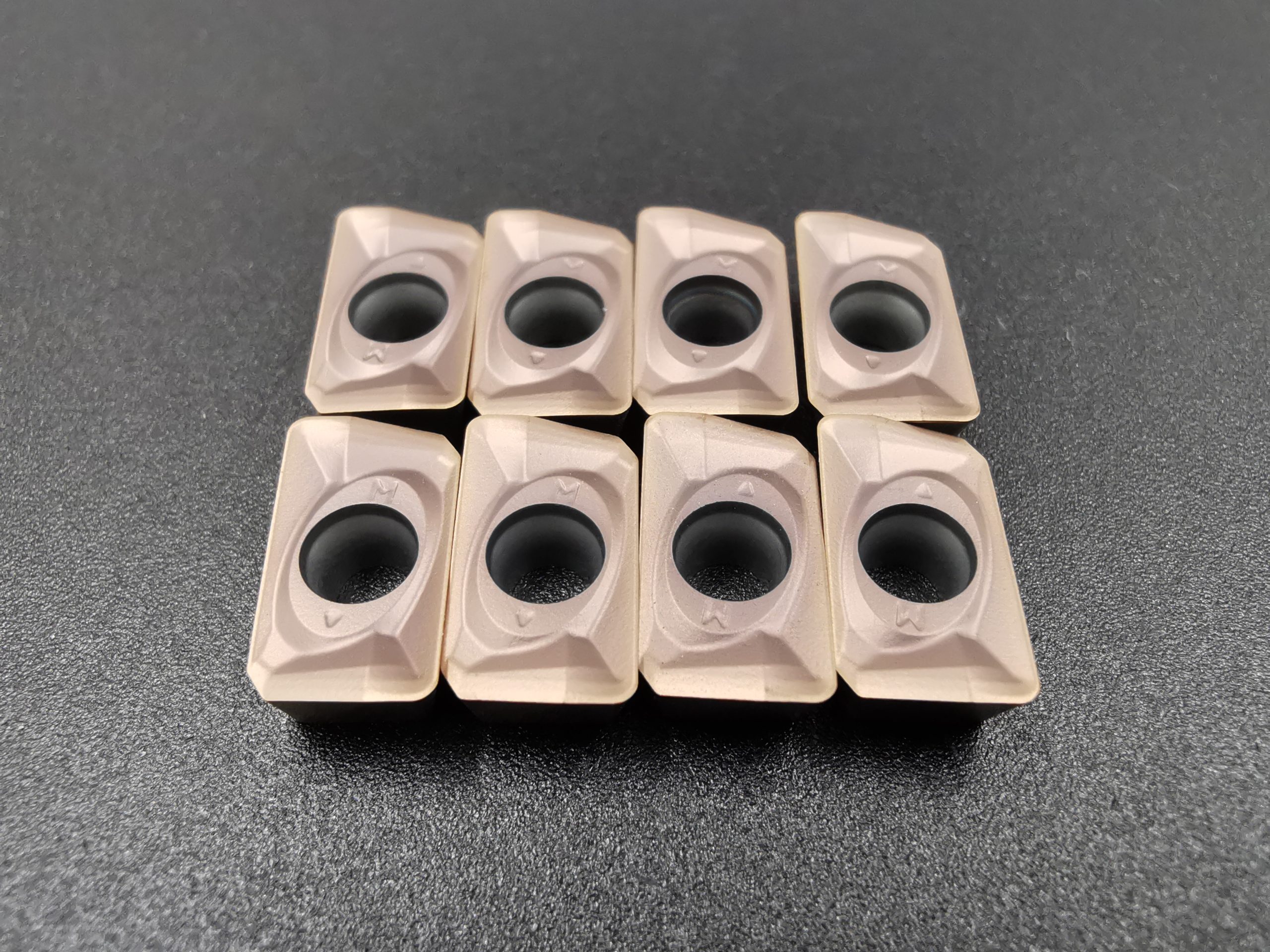

Common Types of APMT Inserts: APMT 1604, APMT 1135

- APMT 1604 Insert: Ideal for high-speed machining of materials like aluminum and steel.

- APMT 1135 Insert: Excellent for finishing cuts in tougher materials like stainless steel and cast iron.

Key Specifications and Features of APMT Inserts

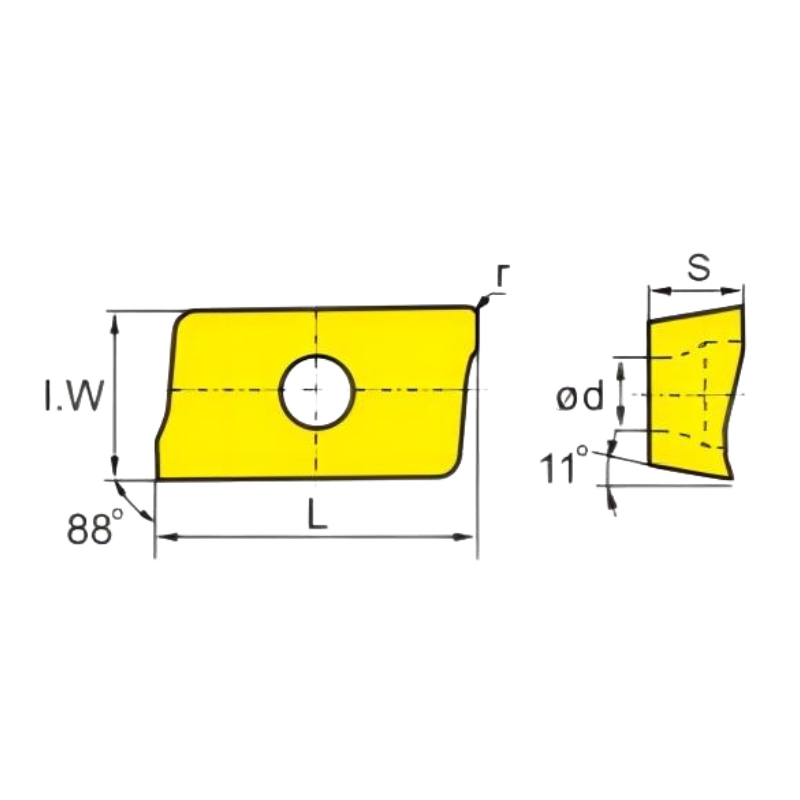

Insert Dimensions: What You Need to Know

The size and geometry of APMT inserts play a key role in their performance. Here’s a look at the dimensions of some common APMT inserts:

| APMT Insert Type | Dimensions (L * S in mm) | Ideal Use |

| APMT 1604 | 17.25 mm x 4.76 mm | High-speed machining of steel and aluminum |

| APMT 1135 | 11.25 mm x 3.5mm | Finishing cuts for stainless steel and cast iron |

Coatings and Materials Used for APMT Inserts

The coating and material of an APMT insert play a significant role in its performance, particularly in terms of wear resistance and heat tolerance. Some common coatings include:

- TiN (Titanium Nitride): Best for cutting low-carbon steels and non-ferrous metals.

- TiAlN (Titanium Aluminum Nitride): Ideal for high-speed cutting, especially for stainless steel and high-temperature alloys.

- CVD Coatings: Provide enhanced durability and are perfect for high-performance turning and milling.

Selecting the Right APMT Insert for Your CNC Operation

How to Choose the Right APMT Insert Based on Material

Choosing the correct insert depends on the material you’re machining. Here’s a quick guide:

- Steel: Use P-grade carbide inserts for general-purpose cutting.

- Aluminum: Choose inserts with a positive rake angle and TiN or TiAlN coatings for smoother cuts.

- Stainless Steel: Opt for M-grade inserts with TiAlN coatings for enhanced heat resistance.

- Cast Iron: Go for K-grade inserts for superior wear resistance and strength.

Understanding Insert Geometry and Rake Angles

The geometry and rake angles of inserts impact their cutting performance. Here’s a basic breakdown:

- Positive Rake Angle: Best for softer materials like aluminum. Reduces cutting forces and improves surface finish.

- Negative Rake Angle: Best for tougher materials like stainless steel. Provides greater stability and strength during machining.

Matching Cutting Speeds and Feed Rates with APMT Inserts

Each APMT insert is optimized for specific cutting speeds and feed rates. It’s important to match your machine’s settings with the insert’s specifications to achieve the best results.

For more information on optimal speeds and feeds, check out Boyo Cutting Tools APMT Inserts.

Comparing APMT Inserts to Other Insert Types

APMT Inserts vs. WNMG, CNMG, TNMG Inserts

While APMT inserts are versatile for both roughing and finishing, other inserts like WNMG, CNMG, and TNMG may be better suited for specific operations. Here’s a quick comparison:

| Insert Type | Best Use | Strengths |

| APMT | General-purpose (roughing & finishing) | Long tool life, smooth cuts |

| WNMG | CNC turning | Excellent chip control and stability |

| CNMG | Turning operations (roughing & finishing) | Stable, durable, and smooth finishes |

Real-World Applications of APMT Inserts in CNC Machining

Case Study 1: APMT Inserts in Steel Machining

APMT 1604 inserts are used effectively in high-speed steel machining, delivering longer tool life and better surface finishes.

Case Study 2: APMT Inserts in Aluminum Milling

For aluminum machining, APMT 1135 inserts with TiN coatings have improved chip flow and reduced cutting forces, leading to increased machining efficiency.

Industry Statistics and Insights

APMT Inserts Performance Data

Here are some real-world statistics on APMT inserts:

- Tool Life: APMT 1604 inserts last 30% longer than conventional inserts when machining steel.

- Cutting Speed: APMT inserts can handle cutting speeds up to 15% higher than non-coated inserts.

- Feed Rate: APMT inserts maintain consistent feed rates without sacrificing surface finish quality.

How Often Should You Replace Your APMT Inserts?

Typically, APMT inserts should be replaced after 100-200 hours of cutting time, depending on the material and operating conditions.

FAQs About APMT Inserts

- What Does APMT Mean?

APMT stands for “Angled Positive Machining Tool,” referring to a type of carbide insert used in CNC machining. - How Do I Know Which APMT Insert to Choose for My CNC Machine?

Consider the material you’re machining, the insert’s geometry, coating, and cutting parameters. - Can APMT Inserts Be Used for Both Roughing and Finishing Operations?

Yes, APMT inserts are highly versatile and can be used for both roughing and finishing operations. - How Long Do APMT Inserts Last?

APMT inserts last longer than traditional inserts, generally lasting 30-50% longer due to their advanced coatings and design.

Final Tips for Getting the Most Out of Your APMT Inserts

- Monitor tool wear and replace inserts promptly to maintain optimal performance.

- Ensure your cutting speed and feed rate are optimized for the material you’re machining.

Conclusion: Choose the Right APMT Insert for Better CNC Performance

By selecting the right APMT insert for your CNC machine, you can significantly improve machining performance, reduce costs, and extend tool life. Whether you’re working with steel, aluminum, or cast iron, Boyo Cutting Tools offers a wide range of high-quality APMT inserts tailored to your machining needs.

Need Help Choosing the Right APMT Insert?

Contact Boyo Cutting Tools today for expert advice and solutions that meet your specific machining requirements. Explore our collection of premium APMT carbide inserts and boost your machining performance!

External Links for More Information: