Key Takeaway

Details

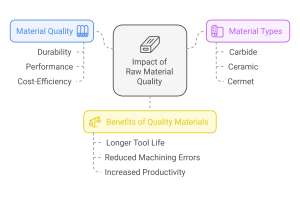

Impact of Material Quality

The quality of raw materials affects durability, performance, and cost-efficiency of CNC inserts.

Material Types

Common CNC insert materials include carbide, ceramic, and cermet.

Benefits of Quality Materials

High-quality materials lead to longer tool life, reduced machining errors, and increased productivity.

Introduction: What Are CNC Inserts and Why Do They Matter?

CNC inserts are small, replaceable cutting tools that play a crucial role in machining operations. They are used in a variety of industries to cut and shape materials with precision. The quality of the raw material used to create CNC inserts directly impacts their performance, wear resistance, and overall efficiency. Understanding the importance of raw material quality will help businesses maximize productivity while minimizing costs.

The Importance of Raw Material Quality in CNC Inserts

What Raw Materials Are Used in CNC Inserts?

CNC inserts are made from the following materials:

- Carbide: Known for its heat resistance and durability, carbide is the most common material used in CNC inserts.

- Ceramic: Ideal for high-speed machining applications, ceramics offer excellent wear resistance and hardness.

- Cermet: A blend of metal and ceramic materials, cermet combines the best properties of both, offering high wear resistance and toughness.

How Does Material Quality Affect Tool Performance?

The quality of raw materials directly affects the performance of CNC inserts. Poor-quality materials can result in premature wear, frequent tool replacements, and poor surface finishes. High-quality materials, on the other hand, lead to:

- Enhanced wear resistance, which reduces tool wear and prolongs tool life.

- Improved cutting efficiency, allowing for faster machining speeds without compromising on quality.

- More consistent machining results, ensuring that products meet strict tolerances and high standards.

Key Factors That Determine CNC Insert Performance

Hardness and Toughness of Raw Materials

The hardness of the raw material affects the CNC insert’s ability to resist wear, while toughness prevents breakage under high stress. The optimal balance of hardness and toughness is essential for high-performance CNC inserts. Too much hardness can make the material brittle, while too little can result in rapid wear.

Impact of Material Impurities on CNC Insert Quality

Impurities in raw materials can degrade the performance of CNC inserts. These impurities can lead to uneven wear, premature failure, and even tool breakage. Therefore, it’s crucial to source materials with minimal impurities to ensure consistent, reliable performance.

The Role of Material Coatings in Performance

Material coatings can significantly enhance the performance of CNC inserts by improving their wear resistance and heat tolerance. Some common coatings include:

- TiN (Titanium Nitride): A popular coating that enhances surface hardness and reduces friction.

- TiAlN (Titanium Aluminum Nitride): Known for its high heat resistance, making it ideal for high-speed machining.

Case Studies: How Quality Raw Materials Improve CNC Insert Performance

Case Study 1: Aerospace Industry

An aerospace manufacturer implemented high-quality carbide inserts for precision machining of turbine blades. By choosing high-quality raw materials, the company achieved:

- A significant increase in tool lifespan.

- Reduced cycle times, improving overall machining efficiency.

- Fewer tool changes, resulting in lower operational costs.

Case Study 2: Automotive Industry

An automotive parts manufacturer switched to cermet inserts for machining hardened steel components. The results included:

- Improved machining precision.

- Cost savings due to fewer tool replacements.

- Higher production rates without sacrificing quality.

Why Choosing High-Quality CNC Inserts Matters

Cost-Effectiveness of Premium CNC Inserts

While high-quality CNC inserts may have a higher upfront cost, their durability and performance lead to significant cost savings over time. Reduced tool wear, fewer replacements, and lower maintenance costs make premium inserts a smart investment.

Increased Machining Efficiency and Productivity

Choosing high-quality CNC inserts can improve machining efficiency by maintaining consistent cutting speeds and high-quality finishes. This means less downtime and faster production, which is critical for businesses that need to meet tight deadlines.

Reducing Environmental Impact

High-quality CNC inserts last longer and require fewer replacements, helping to reduce material waste. This is not only cost-effective but also environmentally friendly, as it minimizes the need for frequent tool disposal and reduces the environmental footprint of machining operations.

Conclusion: Invest in Quality CNC Inserts for Long-Term Success

In conclusion, raw material quality plays a vital role in the performance of CNC inserts. Choosing high-quality materials such as carbide, ceramic, and cermet can lead to enhanced tool durability, improved machining efficiency, and cost savings in the long run. By investing in high-performance CNC inserts, businesses can increase productivity, reduce operational costs, and ensure consistent quality.

Ready to improve your machining processes? Visit our CNC Insert Products page to explore our high-quality cutting tools designed to meet your specific needs.

Frequently Asked Questions (FAQ)

- What is the best material for CNC inserts?

The best material depends on the specific machining needs. Carbide is the most durable and widely used, while ceramic and cermet are ideal for high-speed machining applications.

- How does raw material quality affect the cost of CNC inserts?

Higher-quality materials may have a higher initial cost, but they provide longer tool life, fewer replacements, and greater machining efficiency, leading to significant long-term savings.

- Can CNC inserts be reconditioned?

Yes, many high-quality CNC inserts can be reconditioned, which helps extend their lifespan and reduce overall tool costs.

- How can I tell if a CNC insert is of good quality?

Check for consistent manufacturing, smooth surface finishes, and reliable performance. Reputable manufacturers usually provide detailed product specifications and customer reviews that can help assess quality.

Additional Resources

For more information on CNC inserts, material coatings, and machining processes, feel free to check out our other articles or contact us directly for personalized advice.