CNC inserts are key components used in machining processes like turning, milling, and drilling. These inserts are typically made from materials like carbide, ceramic, or high-speed steel and come in various shapes, sizes, and grades. Each type of insert is designed for a specific application to maximize machining efficiency, tool life, and surface finish. Below, we explore different types of CNC inserts and their applications.

- Carbide Inserts Types

- Grade and Coating:

- Uncoated: Generally used for general-purpose cutting.

- Coated: Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and other coatings improve wear resistance and reduce friction, ideal for high-temperature applications.

- Uncoated: Generally used for general-purpose cutting.

- Applications:

- High-speed cutting, heavy-duty machining, and precision finishing.

- Turning Inserts Types

- Square Inserts (Roughing Inserts):

- Shape: Square shape, four cutting edges.

- Use: Suitable for general turning and facing, providing good stability and chip control.

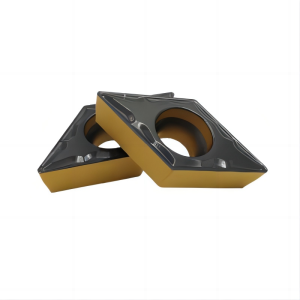

- Diamond Inserts:

-

- Shape: Diamond-shaped, four cutting edges.

- Use: Best for fine turning, finishing, and semi-finishing operations. They provide better surface finishes than square inserts.

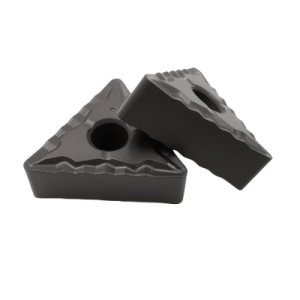

- Triangular Inserts:

-

- Shape: Triangular, three cutting edges.

- Use: Ideal for heavy-duty turning, grooving, and threading. Popular for rough machining.

- Round Inserts:

-

- Shape: Round, multiple cutting edges.

- Use: Suitable for smooth finishes, used for light and medium cutting tasks.

- Milling Inserts Types

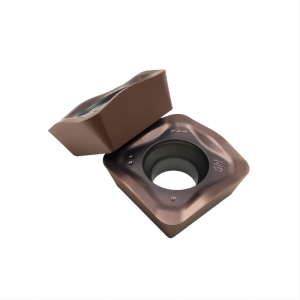

- Indexable Milling Inserts:

-

- Shape: Square, triangular, or round.

- Use: Suitable for light, medium, and heavy milling operations, such as face milling and slot milling.

- Wiper Inserts:

-

- Shape: Typically round or square with a modified edge.

- Use: Specially designed for creating a superior surface finish, reducing the need for secondary finishing operations.

- T-Slot Milling Inserts:

-

- Shape: Specialized inserts designed for T-slot cutters.

- Use: Ideal for cutting T-shaped slots in materials.

- Lathe Inserts Types

- Insert Materials:

- Carbide: Most common due to its hardness and wear resistance.

- Ceramic: Used for high-speed machining of difficult-to-machine materials.

- CBN (Cubic Boron Nitride): Used for hard machining applications.

- Shapes: Square, round, diamond, triangular.

- Applications: Used in lathes for turning operations, threading, and boring.

- CNC Turning Inserts Types

- Positive Inserts:

-

- Shape: Typically, triangular or round.

- Use: Offer high cutting speeds with low cutting forces, ideal for turning soft and ductile materials.

- Negative Inserts:

-

- Shape: Square or rectangular.

- Use: Suitable for heavy-duty cutting, offering better chip control and stability.

- Cutting Inserts Types

- Carbide Inserts: Most commonly used for general turning, milling, and drilling applications due to their hardness and ability to withstand high temperatures.

- Ceramic Inserts: Known for high-speed machining and fine surface finishes, typically used in hard machining applications.

- Cermet Inserts: These inserts combine carbide and metal, offering a balance of wear resistance and toughness, ideal for finishing operations.

- CNC Insert Shapes and Geometries

- Square Inserts: Multi-edged, used for general turning, facing, and light to medium cutting.

- Round Inserts: Designed for precision and finishing applications.

- Triangular Inserts: Used for heavy-duty cutting and high-feed rates.

- Diamond Inserts: Common in finishing, profiling, and light-duty applications.

- Rhombic (Lozenge) Inserts: Suitable for heavy cutting and high rigidity operations.

- Octagonal Inserts: Eight-sided inserts for long tool life and better cost-per-edge.

- Different Types of CNC Inserts Based on Application

- Threading Inserts: Specifically designed for cutting threads, these inserts often come in triangle or diamond shapes.

- Grooving Inserts: Inserts designed to cut grooves and channels in materials, usually with a sharp, narrow edge.

- Drilling Inserts: These inserts are used in the drilling process and are typically round or rectangular in shape.

- Profile Inserts: Used for complex shapes and profiles, they are commonly round or diamond-shaped for smoother cuts.

- Key Factors in Choosing CNC Inserts

- Material to be Machined: Different materials (steel, aluminum, titanium, etc.) require specific insert types for optimal results.

- Cutting Speed: Choose inserts that support the required cutting speed for the job.

- Tool Life and Wear Resistance: Consider inserts with coatings or specialized grades for extended tool life.

- Surface Finish: Wiper inserts are ideal for achieving superior surface finishes with minimal wear.

Conclusion

Choosing the right CNC insert type depends on several factors including the machining process, material being cut, and desired tool life. The variety of insert shapes and materials (carbide, ceramic, CBN) makes it possible to optimize performance for different applications. By understanding the different CNC insert types—including those for turning, milling, and cutting—machinists can significantly improve machining efficiency, reduce costs, and enhance product quality.