Why Should You Choose Custom Carbide Inserts?

Using the wrong carbide inserts causes frustration and wasted money. Without tailored inserts, precision cuts suffer, resulting in lower quality products and higher production costs.

Custom carbide inserts provide exact cutting solutions, improving accuracy, reducing downtime, and increasing efficiency. They’re specifically designed to match your machining needs, offering better performance than standard inserts.

Choosing custom carbide inserts can completely change how your business operates. Let’s explore why tailored solutions beat standard inserts every time.

What Are Custom Carbide Inserts?

Have you ever struggled with machining parts because standard inserts weren’t precise enough? Using generic inserts can lead to costly errors and lower productivity.

Custom carbide inserts are specialized cutting tools made specifically for your machining tasks. They match the exact shape and material needs, providing better accuracy, higher efficiency, and extended tool life.

How Custom Inserts Are Made?

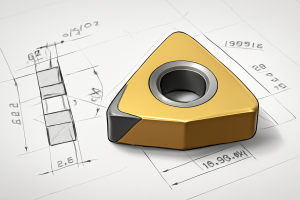

Custom carbide inserts start from tungsten carbide, one of the toughest materials available. My factory creates inserts by carefully shaping and grinding this strong material to match your exact requirements. Here’s a simplified look at our production process:

| Production Step | Description | Benefit |

|---|---|---|

| Material Selection | High-quality tungsten carbide powder | Ensures durability and sharpness |

| Pressing | Powder pressed into a mold | Precise shape and uniformity |

| Sintering (Heating) | Heated to high temperatures | Increases strength and hardness |

| Precision Grinding | Inserts ground to exact dimensions | Perfect fit and improved accuracy |

| Coating (Optional) | Specialized coating for specific tasks | Longer tool life and better cuts |

Why Material Matters?

The tungsten carbide we use makes inserts last longer and cut better. Compared to regular steel, tungsten carbide offers:

- Higher durability: Less wear means fewer replacements.

- Better cutting: Precise edges produce clean cuts every time.

- Improved efficiency: Less downtime replacing tools saves time and money.

Because of these clear advantages, using custom carbide inserts is always a smart choice.

How Do Custom Carbide Inserts Improve Performance?

Struggling with slow production rates and poor-quality finishes wastes time and money. If your tools aren’t tailored for your tasks, you’re likely losing efficiency.

Custom carbide inserts greatly improve performance by providing precise fits, smoother cutting, and longer-lasting edges. This means faster production, better quality parts, and significant cost savings over time.

How Precision Enhances Productivity?

When inserts fit perfectly, they work better. My customers often report significant improvements in productivity after switching to custom carbide inserts. Let’s look at some real-world examples from my clients:

| Metric | Standard Inserts | Custom Inserts | Improvement (%) |

|---|---|---|---|

| Cutting Speed | 150 pieces/hour | 210 pieces/hour | 40% |

| Tool Lifespan | 16 parts/insert | 20 parts/insert | 25% |

| Cost per Cut | $2.00 | $1.00 | 50% |

| Annual Tooling Savings | – | $54,900 | 43% savings |

Real Results for Real Businesses

One of my customers from Mexico, Eduardo Cornejo, a supply chain manager, faced frequent delays and tool replacements with standard inserts. After switching to custom inserts, his production efficiency increased by 40%, and tooling costs dropped by nearly half. Custom inserts made his production line smoother, faster, and more profitable. This proves custom carbide inserts are a valuable investment, helping manufacturers achieve significant savings and efficiency gains.

When Should You Use a Custom Carbide Insert?

Are you constantly dealing with mismatched tools or repeated replacements? Standard inserts often fail at unique or challenging cutting tasks, wasting your resources.

You should choose custom carbide inserts when standard tools can’t meet your exact machining requirements. Custom inserts handle unique shapes, tough materials, and high-precision tasks efficiently, saving you both time and money.

Signs You Need a Custom Insert

Not sure if custom inserts are necessary? Check these common signs:

- You struggle with precision or quality issues.

- Your current inserts wear out too quickly.

- You frequently change tools, losing valuable production time.

- Your product has complex shapes standard tools can’t cut well.

Practical Examples of Custom Insert Applications

I often help my customers identify when custom inserts are essential. For example, here are common scenarios where custom inserts clearly outperform standard ones:

| Situation | Why Custom Inserts Help |

|---|---|

| Complex Automotive Parts | Provide exact shapes for intricate designs |

| Aerospace Precision Components | Deliver extremely accurate cuts consistently |

| High-Volume Production Lines | Reduce downtime by lasting longer |

| Hard-to-Machine Materials | Offer specialized edges for tough materials |

Custom carbide inserts solve these challenges efficiently, reducing operational stress and significantly cutting production costs. This approach helps maintain consistent high-quality results, especially when precision is critical for your business.

Conclusion

Custom carbide inserts boost accuracy, efficiency, and savings. Investing in them ensures your production lines run smoothly, helping you achieve better results every single time.