Are you struggling with inconsistent machining results and premature tool failures? The problem might be with your carbide inserts, not your machine or operators.

Quality carbide inserts are the foundation of efficient machining operations. The journey from raw tungsten powder to finished cutting tools involves precise chemistry, controlled manufacturing processes, and rigorous testing—all factors that determine whether your inserts will deliver peak performance or costly disappointments.

What Are the Essential Raw Materials That Determine Carbide Insert Quality?

Do you know what’s actually inside your cutting tools? Most machinists focus on insert geometry or coating, but the real story begins much earlier—with the raw materials.

High-quality carbide inserts begin with premium tungsten carbide powder (WC) combined with cobalt (Co) as a binder. The precise ratio and purity of these materials, along with grain size control, directly determine the insert’s hardness, toughness, and wear resistance.

The Science Behind Raw Material Selection

The foundation of every carbide insert starts with careful material selection. At Boyo Cutting Tools, we understand that compromising on raw materials means compromising on the final product. Here’s what makes the difference:

Tungsten Carbide Purity

The purity of tungsten carbide dramatically affects performance. Our testing shows that even a 0.5% variation in impurities can reduce tool life by up to 15%. We source only premium-grade tungsten with controlled impurity levels below 0.1%.

The Critical Cobalt Balance

Cobalt serves as the metal binder that holds the tungsten carbide particles together. The percentage of cobalt directly impacts the insert’s properties:

| Cobalt Content | Hardness | Toughness | Best Applications |

|---|---|---|---|

| 6% or less | Very High | Low | Finishing operations, high surface speeds |

| 6-10% | High | Medium | General purpose machining, most popular range |

| 10-15% | Medium | High | Roughing operations, interrupted cuts |

| 15%+ | Low | Very High | Heavy-duty applications, extreme shock resistance |

Our own testing confirms that matching the right cobalt content to the specific application can extend tool life by 30-50% compared to generic inserts.

Grain Size Engineering

The size of tungsten carbide grains in the microstructure is another critical factor:

- Nano-grain (< 0.2 μm): Provides exceptional edge sharpness and wear resistance

- Submicron (0.2-1.0 μm): Balances hardness and toughness for general applications

- Fine grain (1.0-1.3 μm): Greater toughness with good wear resistance

- Medium grain (1.3-2.5 μm): Enhanced shock resistance for interrupted cutting

- Coarse grain (> 2.5 μm): Maximum toughness for severe applications

In our manufacturing facility, we carefully control grain size distributions using advanced milling technology and quality control systems. This precision allows us to produce inserts with consistent performance batch after batch.

How Does the Manufacturing Process Impact Carbide Insert Performance?

Have you ever wondered why two seemingly identical inserts can perform so differently? The secret lies in the manufacturing process—where science meets precision engineering.

The carbide insert manufacturing process involves multiple critical stages: powder preparation, pressing, sintering, grinding, and coating. Each stage must be precisely controlled, as variations in temperature, pressure, or time can create microscopic defects that dramatically reduce performance.

The Critical Manufacturing Steps

At Boyo Cutting Tools, we’ve optimized each manufacturing step to ensure consistent quality. Let me walk you through our process:

Powder Preparation: The First Critical Step

The journey begins with powder preparation, where tungsten carbide and cobalt are mixed in precise ratios. This isn’t simply dumping powders together—it’s a sophisticated process involving:

- Wet ball milling with ethanol and water to create a homogeneous mixture

- Spray drying to produce free-flowing granules with consistent size

- Quality control testing for particle size distribution and chemistry

A uniform powder mixture is essential for preventing structural weaknesses. Our laboratory testing shows that poorly mixed powder can lead to cobalt pooling and 40-60% reduced tool life.

A uniform powder mixture is essential for preventing structural weaknesses. Our laboratory testing shows that poorly mixed powder can lead to cobalt pooling and 40-60% reduced tool life.

Pressing and Pre-Sintering

During pressing, the powder is compressed into the basic insert shape using specialized presses that apply uniform pressure throughout the compact. This step determines:

- The initial density of the insert

- The proper shape dimensions (accounting for shrinkage during sintering)

- The absence of internal cracks or voids

Our process includes both cold isostatic pressing and hydraulic pressing with specialized tooling to ensure uniform density throughout the insert.

Sintering: Transformation Under Heat

Sintering is where the real magic happens—transforming the pressed powder into a solid carbide insert. This process occurs in vacuum furnaces at temperatures between 1350-1500°C. Critical control parameters include:

- Precise temperature control (±5°C throughout the cycle)

- Controlled heating and cooling rates

- Proper atmosphere control to prevent carbon loss

- Uniform heat distribution to prevent warping

Our advanced sintering equipment includes computer-controlled vacuum furnaces with multiple temperature zones to ensure uniform heating. We’ve found that precise sintering control can improve insert toughness by up to 25%.

Grinding and Finishing

After sintering, carbide inserts require precision grinding to achieve their final dimensions and cutting edge properties. Our multi-stage grinding process includes:

- Surface grinding for dimensional accuracy (±0.01mm tolerance)

- Edge preparation for optimized cutting performance

- Micro-finishing for surface quality

Proper edge preparation is particularly critical—our research shows that optimized edge preparation can extend tool life by 35-50% in many applications.

What Role Do Coatings Play in Carbide Insert Quality?

Is your insert failing prematurely despite being the “right grade”? The coating—that microscopically thin layer on the surface—might be the culprit.

Coatings significantly enhance carbide insert performance by providing increased hardness, reduced friction, improved heat resistance, and protection against chemical wear. Modern inserts utilize advanced coating technologies like CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition), with each offering specific benefits for different machining challenges.

Understanding Coating Technologies

At Boyo Cutting Tools, we’ve invested heavily in coating technology because we understand its critical importance to insert performance. Let me explain the key differences:

CVD vs. PVD: Choosing the Right Technology

Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) represent the two primary coating technologies, each with distinct advantages:

| Feature | CVD Coating | PVD Coating |

|---|---|---|

| Thickness | 9-20 microns | 2-3 microns |

| Hardness | Very high | High |

| Adhesion | Excellent | Good |

| Edge Sharpness | Moderate (thicker coating) | Excellent (maintains sharp edge) |

| Temperature Resistance | Superior (up to 1000°C) | Good (up to 800°C) |

| Best Applications | Steel, cast iron, high-speed machining | Superalloys, titanium, stainless steel |

Our production data shows that matching the coating technology to the application can improve tool life by 40-200% compared to uncoated inserts.

Multi-layer Coating Systems

Modern high-performance inserts often feature multi-layer coatings that combine the benefits of different materials:

- TiN (Titanium Nitride): Golden color, provides good wear resistance and reduced friction

- TiCN (Titanium Carbonitride): Improved hardness and toughness compared to TiN

- Al₂O₃ (Aluminum Oxide): Excellent heat and crater wear resistance

- TiAlN (Titanium Aluminum Nitride): Outstanding oxidation resistance at high temperatures

- AlTiN (Aluminum Titanium Nitride): Superior hot hardness for high-temperature machining

Our most advanced inserts feature up to 15 alternating nano-layers, creating a composite coating that outperforms single-layer systems by up to 70% in demanding applications.

Post-Coating Treatments

The performance of coated inserts can be further enhanced through post-coating treatments:

- Edge honing: Creates a controlled micro-radius that strengthens the cutting edge

- Polishing: Reduces friction and improves chip flow

- Surface treatments: Enhances coating adhesion and reduces stress

Through extensive testing, we’ve learned that these treatments can extend tool life by 25-40% in high-demand applications by reducing edge chipping and promoting more consistent wear patterns.

How Can You Identify Common Defects in Carbide Inserts?

Have you ever experienced sudden insert failure that left you puzzled? Understanding common defects can help you identify quality issues before they impact your production.

Common carbide insert defects include porosity, cracks, chipping, uneven coating, and poor edge preparation. These issues stem from raw material problems, manufacturing process control failures, or improper handling. Identifying these defects early prevents costly machining problems and production downtime.

Recognizing and Preventing Quality Issues

At Boyo Cutting Tools, quality control is built into every step of our manufacturing process. Here’s what we’ve learned about identifying and preventing common defects:

Visual Inspection Indicators

Even with the naked eye or a basic magnifying glass, you can spot several quality issues:

- Surface finish inconsistencies: May indicate sintering problems or coating issues

- Color variations: Often signal uneven coating thickness or composition

- Edge irregularities: Could be signs of poor grinding or chipping

- Visible cracks or chips: Obvious structural defects that will lead to failure

Our quality control process includes 100% visual inspection with high-definition electronic magnification to identify even minor defects before inserts leave our facility.

Microstructural Defects and Their Causes

More serious defects require advanced testing techniques but have specific causes:

| Defect Type | Possible Causes | Impact on Performance |

|---|---|---|

| Porosity | Insufficient pressing pressure, improper sintering | Reduced strength, premature failure |

| Cobalt pooling | Poor powder mixing, uneven carbon distribution | Inconsistent wear, weakened structure |

| Grain growth | Excessive sintering temperature or time | Reduced hardness, faster wear |

| Coating delamination | Poor surface preparation, thermal mismatch | Coating flaking, exposure of substrate |

| Edge microchipping | Improper handling, aggressive edge preparation | Poor surface finish, reduced tool life |

Our quality assurance program includes regular destructive testing of sample inserts to identify and address these microscopic defects before they reach customers.

Scientific Quality Control Methods

Modern insert manufacturing requires sophisticated testing methods:

- SEM (Scanning Electron Microscope) analysis: Examines coating adhesion and microstructure at magnifications up to 10,000x

- XRD (X-Ray Diffraction): Verifies coating composition and crystalline structure

- Hardness testing: Confirms the insert meets specified hardness requirements

- Transverse rupture strength testing: Measures the insert’s resistance to breakage

These advanced testing methods help us maintain consistent quality across all our production lines.

Real-World Performance Testing

The ultimate test for insert quality is real-world performance. Our testing laboratory includes:

- CNC machining centers that replicate customer environments

- Accelerated wear testing protocols

- Surface finish and dimensional stability measurements

- Tool life comparisons against benchmark inserts

This practical testing ensures our inserts not only meet technical specifications but deliver the performance our customers expect in their actual production environments.

How Do You Select the Right Grade for Specific Applications?

Are your tools wearing out too quickly or producing poor surface finishes? You might be using the right insert shape but the wrong grade for your application.

Selecting the correct carbide insert grade involves matching the insert’s properties to your specific machining parameters. Consider workpiece material hardness, cutting conditions (continuous vs. interrupted), machining parameters (speed, feed, depth), and desired surface finish when choosing between harder grades for wear resistance or tougher grades for impact resistance.

The Science of Grade Selection

At Boyo Cutting Tools, we’ve developed a systematic approach to grade selection based on years of application experience:

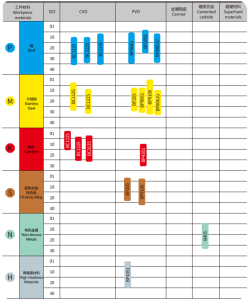

Understanding the ISO Classification System

The ISO system classifies carbide grades into three main categories:

- P series (blue): For machining steel

- M series (yellow): For machining stainless steel and dual-purpose applications

- K series (red): For machining cast iron, non-ferrous metals, and non-metallics

Within each category, grades are numbered from 01 to 50, with lower numbers indicating harder grades for finishing operations and higher numbers indicating tougher grades for roughing.

Workpiece Material Considerations

The workpiece material is the most important factor in grade selection:

| Material Type | Recommended Grade Characteristics | Example Applications |

|---|---|---|

| Carbon Steel | Medium hardness, good wear resistance | General machining, automotive components |

| Hardened Steel | High hardness, thermal resistance | Tool & die work, hardened components |

| Stainless Steel | Chemically resistant coating, sharp edge | Medical devices, food processing equipment |

| Cast Iron | Good thermal conductivity, wear resistance | Engine blocks, pump housings |

| Non-ferrous (Al, Cu) | Sharp edges, polished surfaces | Electronics, consumer goods |

| Superalloys | Thermal stability, edge strength | Aerospace, power generation |

Our technical support team works closely with customers to analyze material characteristics and recommend the optimal grade for their specific workpiece.

Operation Type and Cutting Conditions

The nature of the cutting operation significantly impacts grade selection:

- Continuous cutting (like turning on a solid diameter): Benefits from harder grades with superior wear resistance

- Interrupted cutting (like milling or turning with slots): Requires tougher grades that resist chipping

- Heavy roughing: Needs maximum toughness to withstand high cutting forces

- Precision finishing: Requires hardness and edge stability for dimensional accuracy

We’ve found that matching the grade to the cutting conditions can extend tool life by 30-100% compared to using a general-purpose grade.

The Cutting Parameters Matrix

For optimal grade selection, consider the relationship between cutting speed, feed rate, and depth of cut:

- High speed/low feed: Generates heat, requires grades with thermal resistance

- Low speed/high feed: Creates mechanical stress, needs tougher grades

- Heavy depth of cut: Demands grades with good edge strength

- Light finishing cuts: Benefits from harder grades with good edge retention

Our technical engineers can help you analyze your specific cutting parameters to find the ideal grade for maximum performance.

What Economic Benefits Come From Investing in Quality Inserts?

Are you focusing too much on the purchase price of inserts while ignoring the true cost of machining? This narrow view might actually be increasing your overall production costs.

High-quality carbide inserts deliver significant economic benefits beyond their initial cost, including extended tool life, reduced machine downtime, consistent part quality, higher cutting parameters, and lower labor costs for tool changes. The total cost of machining can be reduced by 15-30% despite a potentially higher insert purchase price.

Calculating the True Cost of Machining

At Boyo Cutting Tools, we help our customers look beyond the simple price per insert to understand the total economic impact of insert quality:

The Total Machining Cost Equation

The comprehensive cost of machining includes multiple factors:

- Insert cost: The direct purchase price of the inserts

- Machine time cost: The hourly cost of running the machine

- Labor cost: Operator time for production and tool changes

- Downtime cost: Lost production during tool changes and unexpected failures

- Quality cost: Scrap, rework, and inspection related to cutting tool performance

Our analysis with customers consistently shows that insert cost represents only 3-5% of the total machining cost, while the insert’s performance impacts the remaining 95-97%.

Tool Life Impact on Overall Economics

Extended tool life from quality inserts delivers multiple economic benefits:

| Tool Life Improvement | Economic Benefits |

|---|---|

| 25% longer life | • 20% fewer tool changes<br>• 5-10% reduced machine downtime<br>• 3-6% lower labor costs |

| 50% longer life | • 33% fewer tool changes<br>• 10-15% reduced machine downtime<br>• 7-12% lower labor costs |

| 100% longer life | • 50% fewer tool changes<br>• 15-25% reduced machine downtime<br>• 12-20% lower labor costs |

Our performance testing program helps customers quantify these benefits for their specific applications.

Performance Parameters and Productivity

Quality inserts also enable higher cutting parameters, directly impacting productivity:

- Higher cutting speeds: Increase parts produced per hour

- Greater feed rates: Reduce cycle time per part

- Deeper cuts: Remove material more efficiently

- More consistent performance: Reduce the need for conservative machining parameters

In a recent customer case study, we documented a 35% increase in metal removal rate with our premium inserts while maintaining the same tool life as their previous solution.

Quality and Consistency Benefits

Beyond tool life and cutting parameters, high-quality inserts provide:

- Consistent part dimensions: Reducing inspection and rework costs

- Better surface finishes: Eliminating secondary operations

- Predictable performance: Allowing for more accurate production scheduling

- Fewer catastrophic failures: Reducing the risk of damaged workpieces

These quality benefits often translate to 5-15% cost savings that don’t appear in basic tool cost calculations.

Conclusion

Understanding carbide insert quality isn’t just technical knowledge—it’s a key competitive advantage. From raw materials to manufacturing processes, coatings, defect prevention, and grade selection, quality impacts every aspect of machining performance and economics. Investing in premium carbide inserts isn’t an expense—it’s a strategic decision that drives productivity and profitability.