Struggling with poor tool life and inefficient machining when cutting steel? You’re not alone. Many manufacturers face challenges when selecting the right carbide inserts for steel machining.

The best carbide CNC inserts for steel machining should balance wear resistance and toughness, ensuring long tool life and high precision. Choosing the right insert grade, coating, and cutting parameters is essential for optimal performance.

Carbide CNC Inserts for Steel Machining

Choosing the right carbide insert can make or break your machining efficiency. Let’s explore the key aspects of machining steel with carbide CNC inserts and how to maximize productivity.

What Are the Key Challenges of Machining Steel?

Machining steel is challenging due to high cutting forces, heat generation, and tool wear. Without the right carbide insert, chipping, premature failure, and poor surface finish can occur.

Challenges in Steel Machining

Understanding Steel Machining Difficulties

- High cutting forces: Steel is tough, requiring strong inserts.

- Excessive heat: Poor heat dissipation can reduce tool life.

- Built-up edge (BUE): Steel can stick to the tool, causing defects.

- Vibration issues: If not controlled, vibration affects accuracy.

Using coated carbide inserts with high heat resistance can significantly improve results.

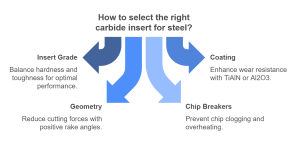

How to Select the Right Carbide Insert for Steel?

Choosing the correct carbide grade, coating, and geometry ensures high efficiency, long tool life, and excellent surface finish.

Key Factors to Consider

| Factor | Recommendation |

| Insert Grade | Use a balance of hardness and toughness (e.g., ISO P20-P30). |

| Coating | TiAlN or Al2O3 coatings improve wear resistance. |

| Geometry | Positive rake angles reduce cutting forces. |

| Chip Breakers | Prevent chip clogging and overheating. |

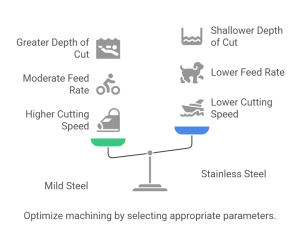

What Are the Best Cutting Parameters for Steel Machining?

Optimizing speed, feed rate, and depth of cut improves efficiency and prolongs tool life.

Recommended Cutting Parameters for Carbide Inserts

| Material Type | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) |

| Mild Steel | 200-300 | 0.15-0.25 | 1.0-3.0 |

| Alloy Steel | 150-250 | 0.10-0.20 | 1.0-2.5 |

| Stainless Steel | 100-200 | 0.08-0.15 | 0.5-2.0 |

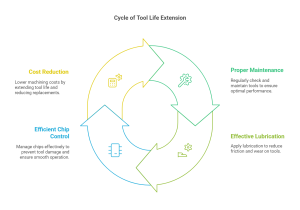

How to Extend Tool Life and Reduce Costs?

Proper maintenance, lubrication, and chip control can extend tool life and reduce machining costs.

Best Practices to Improve Tool Longevity

- Use proper coolant to manage heat and prevent insert failure.

- Monitor wear patterns and replace inserts before they fail.

- Optimize tool paths to reduce unnecessary stress on the insert.

- Choose stable tool holders to minimize vibration and improve accuracy.

Conclusion

Using the right carbide CNC inserts and machining parameters can drastically improve efficiency, reduce tool wear, and cut costs. Selecting the correct insert grade, coating, and cutting speed ensures high-quality machining results.

For premium carbide inserts, visit BOYO Cutting Tools.