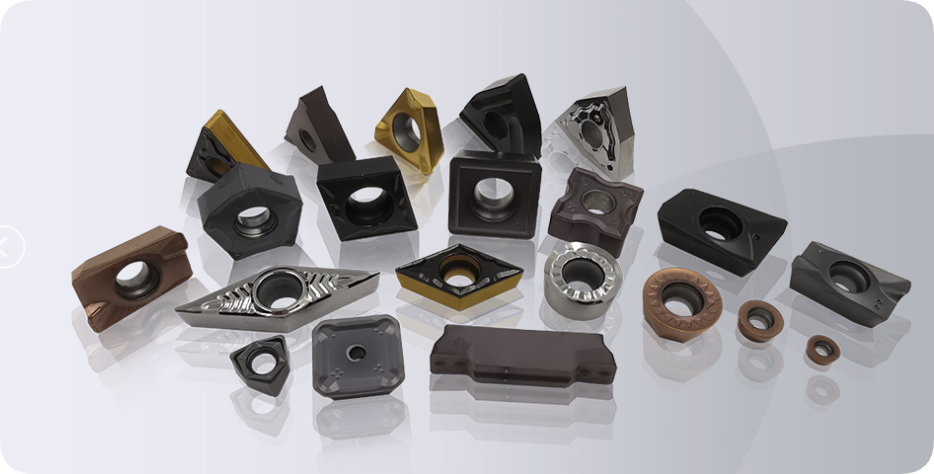

Are you wasting thousands of dollars on the wrong cutting tool inserts? I’ve seen countless manufacturers struggle with tool failures, poor surface finishes, and skyrocketing production costs due to improper insert selection.

The key to matching insert types with suppliers lies in understanding four critical factors: material compatibility, geometric considerations, coating technologies, and application requirements. When these align with a supplier’s capabilities, you’ll achieve optimal performance, extended tool life, and significant cost savings.

I’ve been in the cutting tool business for over 15 years, and I can tell you that finding the perfect match between insert types and suppliers isn’t just about price – it’s about unlocking maximum productivity. Let me show you how to make the right choice every time.

What Factors Should You Consider When Selecting Cutting Tool Insert Materials?

Do you know that using the wrong insert material can reduce your tool life by up to 70%? I’ve visited hundreds of manufacturing facilities where this simple mistake was draining their profitability.

The optimal insert material depends primarily on your workpiece material, cutting conditions, and surface finish requirements. Carbide inserts work best for most general applications, while ceramics excel in high-speed machining, PCD is ideal for non-ferrous materials, and CBN performs exceptionally with hardened steels.

The Critical Impact of Workpiece Material

When selecting insert materials, your workpiece material should always be your starting point. I remember visiting a client in Mexico who was machining titanium aerospace components with standard carbide inserts. Their tool life was abysmal – less than 10 minutes per edge! After switching to specialized PVD-coated grades designed specifically for titanium, their tool life increased to over 45 minutes.

Here’s a breakdown of the most common insert materials and their ideal applications:

| Insert Material | Best For | Advantages | Limitations |

| Cemented Carbide | Steel, cast iron, general-purpose | Versatility, good balance of wear resistance and toughness | Less effective with super alloys |

| Ceramic | High-speed machining of hardened materials | Superior heat resistance, enables very high cutting speeds | Brittle, poor thermal shock resistance |

| PCD (Polycrystalline Diamond) | Non-ferrous materials (aluminum, copper, composites) | Exceptional wear resistance, superior surface finish | Cannot be used on ferrous materials, expensive |

| CBN (Cubic Boron Nitride) | Hardened steels, cast iron | Excellent for hard materials (>45 HRC), maintains sharp edge | High cost, limited application range |

| Cermet | Finishing operations on steel | Superior surface finish, reduced built-up edge | Limited toughness for interrupted cuts |

The Role of Cutting Conditions

The environment in which you’re cutting plays a massive role in insert selection. I’ve consulted with a client in Indonesia who was experiencing premature tool failure in a high-temperature, wet machining environment. By switching from a standard coating to a specialized AlTiN coating designed for these conditions, their tool life doubled.

Consider these cutting conditions when selecting your insert material:

- Continuous vs. Interrupted Cutting: Interrupted cutting requires tougher grades with better impact resistance

- Dry vs. Wet Machining: Some coatings perform better with coolant, others in dry conditions

- Rigidity of Setup: Less rigid setups require tougher insert grades to withstand vibration

- Cutting Speed: Higher speeds generally require more wear-resistant materials and coatings

- Depth of Cut: Deeper cuts demand tougher grades to withstand higher cutting forces

Surface Finish Requirements

Your desired surface finish will significantly influence your material selection. In my experience working with precision component manufacturers, I’ve found that the insert material directly impacts the achievable surface finish. For mirror-like finishes under Ra 0.2μm, diamond-polished PCD or fine-grain carbide with specialized coatings is often necessary.

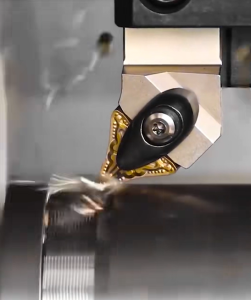

How Do Different Insert Geometries Affect Machining Performance?

Have you ever wondered why your perfectly good insert is causing chatter or producing poor surface finish? I’ve diagnosed hundreds of machining problems where the issue wasn’t the insert quality, but simply the wrong geometry for the application.

Insert geometry directly influences cutting forces, chip evacuation, and surface finish. Round inserts provide strength and multiple cutting points, triangle inserts offer sharper cutting action, square inserts balance versatility with strength, while diamond inserts excel at profiling and finishing operations.

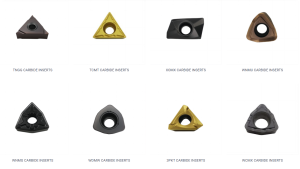

Decoding Insert Shapes and Their Ideal Applications

The shape of your insert is far more important than most people realize. Last year, I worked with a tool manufacturer in Brazil who was struggling with edge chipping on their threading inserts. By switching from a 55° diamond insert to a more robust 80° diamond with a reinforced cutting edge, their edge life improved by 300%.

Here’s a comprehensive breakdown of insert shapes and their specialized applications:

Round Inserts

Round inserts distribute cutting forces evenly and offer multiple cutting points. They’re excellent for:

- Heavy roughing operations

- High feed applications

- Materials prone to work hardening

- Applications requiring strong cutting edges

The drawback is less precision for square shoulders or detailed features.

Triangle Inserts

Triangle inserts provide:

- Sharper cutting action

- Three usable cutting edges

- Good accessibility in tight spaces

- Excellent for light to medium cutting

However, they typically offer less edge strength than square or round inserts.

Square Inserts

Square inserts deliver:

- Four usable cutting edges

- Good balance between strength and versatility

- Capability for both roughing and semi-finishing

- Effective for 90° shoulder milling

Diamond (Rhombic) Inserts

Diamond inserts excel at:

- Profiling operations

- Finishing cuts

- Creating chamfers and bevels

- Applications requiring specific approach angles

Nose Radius Considerations

The nose radius of your insert dramatically affects surface finish and tool strength. I visited a client in Germany who was experiencing poor surface finish in their aerospace components. By simply increasing their insert nose radius from 0.4mm to 0.8mm, their surface finish improved from Ra 3.2 to Ra 0.8 without any other changes.

Consider these factors when selecting nose radius:

- Larger radius = better surface finish but higher cutting forces

- Smaller radius = sharper cutting action but reduced strength

- Application-specific requirements (thread pitches, groove widths)

- Material characteristics (ductile materials often benefit from larger radii)

Chip Control Features

Modern insert geometries incorporate sophisticated chip control features. These aren’t just marketing gimmicks – they significantly impact performance. I worked with an automotive parts manufacturer in Turkey who was having severe chip tangling issues in a lights-out operation. By switching to inserts with advanced chip-breaking geometries, they eliminated unplanned downtime caused by chip nests.

Key chip control considerations include:

- Chip Breakers: Designed for specific feed ranges and materials

- Rake Angles: Positive rakes reduce cutting forces but weaken the edge

- Land Width: Wider lands increase edge strength but may increase cutting forces

- Gullet Size: Affects chip evacuation in deep cuts

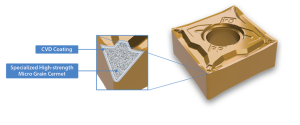

What Role Do Coating Technologies Play in Insert Performance?

Did you know that the right coating can increase your tool life by up to 500%? I’ve seen companies waste enormous sums on premium carbide grades when a simple coating change would have solved their problems at a fraction of the cost.

Insert coatings dramatically improve wear resistance, reduce friction, increase heat resistance, and prevent chemical reactions with workpiece materials. CVD coatings provide superior wear resistance for steel and cast iron, while PVD coatings offer better edge strength for difficult-to-machine materials like titanium and superalloys.

Understanding Modern Coating Technologies

The science behind cutting tool coatings has advanced dramatically in recent years. When I started in this industry, we had basic TiN coatings. Now, we have multi-layer nano-coatings that precisely target specific application challenges.

CVD Coatings (Chemical Vapor Deposition)

CVD coatings are applied at high temperatures (around 1000°C) and are characterized by:

- Thickness of 5-20 microns

- Excellent wear resistance

- Strong bonding to the substrate

- Superior resistance to crater wear on the rake face

Common CVD coatings include:

- TiCN (Titanium Carbonitride): Good balance of wear resistance and toughness

- Al2O3 (Aluminum Oxide): Excellent heat barrier, chemical stability

- TiN (Titanium Nitride): Good all-around performance, gold color

- MT-CVD: Medium-temperature process that preserves substrate toughness

PVD Coatings (Physical Vapor Deposition)

PVD coatings are applied at lower temperatures (400-600°C) and offer:

- Thinner layers (1-4 microns)

- Sharper cutting edges

- Better edge toughness

- Compressive stress that increases fracture resistance

Popular PVD coatings include:

- AlTiN (Aluminum Titanium Nitride): Excellent heat resistance

- TiAlN (Titanium Aluminum Nitride): Good for high-speed applications

- ZrN (Zirconium Nitride): Reduces built-up edge in non-ferrous materials

- DLC (Diamond-Like Carbon): Ultra-low friction for non-ferrous materials

Material-Specific Coating Recommendations

Based on my years of experience working with various industries, here are my recommendations for specific materials:

| Workpiece Material | Recommended Coating | Key Benefits |

| Carbon Steel | TiCN+Al2O3+TiN (CVD) | Maximum wear resistance, good heat barrier |

| Stainless Steel | AlTiN or TiAlN (PVD) | Reduced built-up edge, better heat resistance |

| Cast Iron | Al2O3-based (CVD) | Excellent abrasion resistance |

| Aluminum | DLC or ZrN (PVD) | Prevents aluminum adhesion, reduces built-up edge |

| Titanium | AlTiN or TiB2 (PVD) | Heat resistance, reduced chemical affinity |

| Superalloys | AlCrN or TiSiN (PVD) | Maximum heat resistance, oxidation resistance |

I remember working with a medical device manufacturer who was machining implant-grade titanium. They were experiencing severe edge buildup and premature failure with standard coatings. After switching to a specialized TiB2 coating designed specifically for titanium, their tool life increased by 400%, and surface quality dramatically improved.

How Can You Evaluate and Select the Best Insert Suppliers?

Are you struggling with inconsistent quality from your current insert suppliers? This is a common problem I see across industries. Just last month, I consulted with a manufacturer in Vietnam who was experiencing 30% variation in tool life between batches from their supplier.

The best insert suppliers offer consistent quality, comprehensive technical support, reliable delivery, competitive pricing, and a wide range of solutions. Look for suppliers with ISO certifications, application engineering capabilities, inventory management programs, and a track record of innovation and problem-solving.

Key Criteria for Supplier Evaluation

After working with hundreds of manufacturers globally, I’ve developed a systematic approach to evaluating cutting tool suppliers. Here are the critical factors you should consider:

Manufacturing Capabilities and Quality Control

The foundation of any good insert supplier is their manufacturing process and quality control systems. When I visit potential suppliers, I always ask about:

- Raw Material Sourcing: Premium carbide powder sources and quality

- ISO Certifications: At minimum, ISO 9001 and ideally ISO 14001

- Production Equipment: Modern sintering, grinding, and coating equipment

- Inspection Protocols: SEM analysis, hardness testing, coating thickness verification

- Batch Consistency: Statistical process control methods

- Substrate Formulation Control: Precise control of cobalt content and grain size

I recently toured a manufacturer’s facility in India and was impressed by their investment in automated inspection systems that measured each insert for dimensional accuracy within ±3 microns. This level of precision directly translates to consistency in your machining process.

Technical Support and Application Expertise

The best suppliers don’t just sell you a product; they help you solve problems. Look for suppliers who offer:

- Application engineers with real-world machining experience

- Free cutting trials and process optimization

- Training programs for your operators

- Troubleshooting support when issues arise

- Customized solutions for challenging applications

I’ve worked with a supplier who went so far as to develop a custom insert grade specifically for a client’s difficult-to-machine nickel alloy. This level of partnership is invaluable.

Supply Chain Reliability

In today’s volatile global environment, supply chain reliability is more critical than ever. Evaluate:

- Typical lead times and emergency response capabilities

- Inventory management programs and VMI options

- Geographic diversification of manufacturing facilities

- Transportation partnerships and logistics expertise

- Track record during previous supply chain disruptions

One of my clients in the USA switched to a supplier with a local regrinding and recoating facility. This reduced their lead times from 8 weeks to just 3 days for specialized inserts.

Value Beyond Price

While competitive pricing is important, the true value of a supplier extends far beyond the unit price. Consider:

- Total cost of ownership, including tool life and productivity

- Process improvement expertise that can reduce overall costs

- Regrinding and reconditioning services

- Custom solutions for specific challenges

- Technical documentation and resources

Building Strategic Supplier Relationships

The most successful manufacturers I work with don’t just have vendors; they have strategic partners. Here’s how to develop these relationships:

- Share Information: Provide your suppliers with application details, production goals, and challenges

- Collaborative Problem-Solving: Involve suppliers in improvement initiatives

- Performance Feedback: Regular reviews of tool performance and supplier service

- Long-Term Planning: Include suppliers in discussions about future production needs

- Technology Exchange: Be open to new solutions and technologies

I’ve seen these partnerships lead to dramatic improvements in productivity and cost reduction. One automotive supplier I worked with reduced their overall tooling costs by 23% while increasing production by 15% through a strategic partnership with their insert supplier.

Conclusion

Matching the right insert types with quality suppliers is a critical decision that directly impacts your productivity, part quality, and bottom line. By understanding insert materials, geometries, coatings, and supplier evaluation criteria, you can make informed choices that drive success.