Are you struggling with premature insert failure and poor surface finish despite using quality aluminum-specific inserts? The problem might be your cooling strategy, an often-overlooked aspect of aluminum machining that can make or break your results.

Effective cooling strategies for aluminum include high-pressure coolant (500+ PSI) directed at the cutting edge, flood cooling with proper nozzle positioning, and minimum quantity lubrication (MQL) with aluminum-specific formulations. Proper cooling prevents built-up edge, extends insert life, and improves surface finish.

I visited a shop that was replacing inserts every 20 minutes when machining large aluminum components. Their coolant was poorly directed, with nozzles aimed generally at the cutting zone rather than precisely at the cutting edge. After repositioning the nozzles and increasing pressure, tool life extended to over 90 minutes, and surface finish improved dramatically.

High-Pressure Coolant: The Game Changer

High-pressure coolant delivery has revolutionized aluminum machining in recent years:

Benefits of High-Pressure Cooling

- Superior chip evacuation: Forces chips away from the cutting zone immediately

- Enhanced cooling effect: Penetrates the boundary layer for more effective heat removal

- Built-up edge prevention: Continuously cleans the cutting edge during machining

- Extended insert life: Typically increases tool life by 50-100% compared to conventional cooling

Implementation Considerations

To effectively implement high-pressure cooling for aluminum:

- Pressure requirements: 500-1,000 PSI (35-70 bar) is typically optimal

- Nozzle positioning: Direct precisely at the cutting edge-chip interface

- Nozzle diameter: Smaller diameter (0.5-1.0mm) creates more focused jet

- Flow rate: 1-2 gallons per minute per nozzle is typically sufficient

One aerospace customer implemented high-pressure coolant for their aluminum structural components and saw tool life increase from 45 minutes to over 3 hours per edge, while also increasing cutting speed by 30%.

Conventional Flood Cooling: Optimizing What You Have

Not every shop has high-pressure capability, but conventional flood cooling can still be highly effective when properly implemented:

Maximizing Conventional Cooling Effectiveness

- Volume over pressure: With conventional cooling, abundant flow is key

- Multiple nozzle approach: Use several nozzles to cover all cutting areas

- Nozzle positioning: Aim directly at the cutting edge, not just the general area

- Coolant maintenance: Regular concentration checks and filtration are critical

Common Coolant Mistakes to Avoid

- Insufficient flow: Too little coolant can be worse than none at all

- Poor concentration management: Incorrect mix ratios reduce effectiveness

- Contamination: Tramp oil and debris significantly reduce cooling efficiency

- Nozzle neglect: Clogged or misaligned nozzles render cooling ineffective

| Cooling Method | Pressure Range | Best For | Limitations | Tool Life Impact |

| High-Pressure | 500-1,000+ PSI | High-speed machining, difficult alloys | Equipment cost, mist control | +50-100% |

| Conventional Flood | 50-100 PSI | General-purpose aluminum machining | Less effective at high speeds | Baseline |

| MQL | N/A (mist) | Environmental concerns, certain operations | Not suitable for all applications | +20-40% |

| Dry Cutting | N/A | Not recommended for most aluminum cutting | Very limited applications | -50-70% |

Minimum Quantity Lubrication (MQL): The Environmental Option

MQL provides an alternative approach that some shops prefer for environmental or specific application reasons:

MQL Benefits for Aluminum

- Reduced environmental impact: Minimal fluid consumption and disposal

- Cleaner parts: Less cleanup required after machining

- Better visibility: Clear view of the cutting operation

- Effective lubrication: Can be highly effective with proper application

MQL Implementation for Aluminum

For effective MQL with aluminum:

- Aluminum-specific formulations: Use lubricants designed for non-ferrous materials

- Proper delivery system: Internal delivery through the tool is highly preferable

- Application rate: Typically 5-50 ml/hour depending on operation size

- Combined approaches: Some applications benefit from MQL plus cold air

Coolant Selection for Aluminum

The type of coolant used can significantly impact aluminum machining performance:

- Semi-synthetic coolants: Often the best balance for aluminum machining

- Synthetic coolants: Can be effective but may have less lubricity

- Soluble oils: Good lubricity but may cause staining on some alloys

- Aluminum-specific additives: Look for formulations with specific aluminum enhancers

I worked with one medical device manufacturer to select the optimal coolant formulation for their high-precision aluminum components. By switching to an aluminum-specific semi-synthetic coolant and implementing proper concentration management, they reduced surface finish variation by 65% and virtually eliminated the staining issues they had been experiencing.

How Can I Troubleshoot and Solve Common Aluminum Machining Problems?

Are you constantly battling with poor surface finish, premature tool wear, or dimensional issues when machining aluminum? Many shops waste valuable time and materials by treating symptoms rather than identifying and addressing root causes.

Most aluminum machining problems stem from built-up edge formation, improper chip control, or thermal issues. Troubleshooting should focus on checking insert geometry (ensure sharp edges and proper rake angles), optimizing cutting parameters (typically increasing speed), improving cooling application, and selecting aluminum-specific inserts.

A customer called me in a panic about scrapping dozens of expensive aluminum aerospace components due to poor surface finish. After a systematic troubleshooting approach, we identified that their coolant concentration had dropped to just 3% (instead of the required 8%), causing built-up edge and surface smearing. After correcting the concentration and switching to a more appropriate insert geometry, the problem was completely resolved.

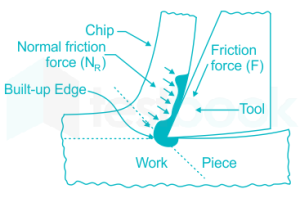

Diagnosing Built-Up Edge (BUE) Issues

Built-up edge is the most common and problematic issue when machining aluminum:

Identifying BUE Problems

Look for these tell-tale signs:

- Dull, shiny deposits on the cutting edge of the insert

- Poor surface finish with smearing or tearing

- Inconsistent dimensions from one part to the next

- Reduced tool life despite proper handling

Common Causes of BUE

- Inappropriate insert geometry: Insufficient rake angle or edge sharpness

- Surface roughness of insert: Non-polished rake faces or worn coatings

- Inadequate cutting speed: Running too slow is a primary cause

- Poor cooling application: Insufficient or improperly directed coolant

- Incorrect insert material: Using inserts not designed for aluminum

Solutions for BUE

- Increase cutting speed: Often the simplest and most effective solution

- Verify insert specification: Ensure you’re using aluminum-specific inserts

- Check insert condition: Replace worn or damaged inserts immediately

- Upgrade cooling system: Improve placement, pressure, or concentration

- Consider material coating: For problematic alloys, try diamond-coated or PCD inserts

Resolving Poor Surface Finish

Surface finish problems in aluminum can stem from several factors:

Causes of Surface Finish Issues

- Feed rate mismatches: Either too high or too low for the application

- Inappropriate nose radius: Not suited for the required finish

- Chip control problems: Re-cutting chips damages the surface

- Tool vibration: Insufficient rigidity in setup or tooling

- Material properties: Some alloys are naturally more difficult to finish

Surface Finish Improvement Strategies

| Problem | Symptom | Solution |

| Feed marks | Regular pattern on surface | Reduce feed or increase nose radius |

| Smearing | Plastic deformation of surface | Sharper cutting edge, increase speed |

| Chatter | Wavy pattern, vibration marks | Improve rigidity, adjust speed/feed |

| Dull finish | Lack of brightness, cloudy appearance | Verify cooling, check for BUE |

| Torn surface | Irregular tears in material | Sharper inserts, proper rake angle |

Chip Control Challenges

Aluminum’s tendency to form long, stringy chips creates unique control challenges:

Effective Chip Management

- Select appropriate chip breakers: Use aluminum-specific designs with open geometries

- Optimize cutting parameters: Adjust speed and feed to create well-formed chips

- Consider interrupted cutting techniques: Programmed interruptions can break chips

- Ensure adequate coolant: High-pressure coolant helps break and evacuate chips

I worked with one medical device manufacturer who was experiencing persistent chip tangling issues when machining aluminum valve bodies. By switching to inserts with aluminum-specific chip breakers and implementing high-pressure coolant, they eliminated the problem completely, reducing machine downtime by over 85%.

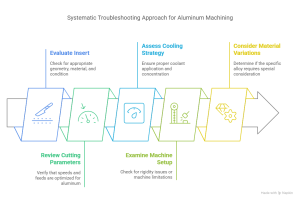

Systematic Troubleshooting Approach

When facing aluminum machining problems, follow this systematic approach:

- Evaluate the insert first: Check for appropriate geometry, material, and condition

- Review cutting parameters: Verify that speeds and feeds are optimized for aluminum

- Assess cooling strategy: Ensure proper coolant application and concentration

- Examine the machine setup: Check for rigidity issues or machine limitations

- Consider material variations: Determine if the specific alloy requires special consideration

This methodical approach has helped hundreds of my customers quickly identify and resolve aluminum machining issues, saving them thousands of dollars in scrapped parts and lost productivity.

Conclusion

Choosing the best carbide inserts for aluminum machining requires understanding aluminum’s unique properties and selecting tools specifically designed for these challenges. Focus on sharp edges, positive rake angles, polished surfaces, and aluminum-specific chip breakers. Match insert material to your production volume and quality requirements, and don’t forget the critical importance of proper cooling strategies.

If you need reliable carbide inserts with premium materials, precision engineering, fast delivery, and consistent quality, contact us at sales@boyocuttingtools.com or visit www.boyocuttingtools.com.